What is a churn test on a fire pump?

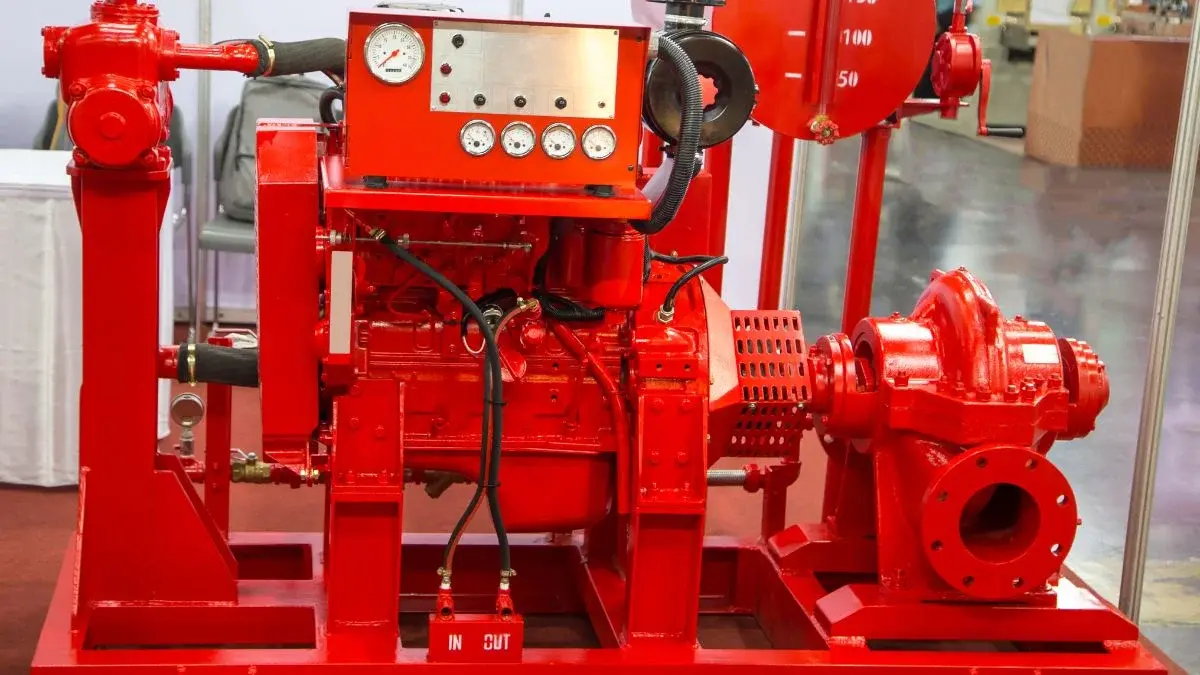

Fire pumps give water-based systems the necessary pressure rise, but their efficiency depends on proper design, installation, evaluation, and ongoing maintenance after installation. The “keys” that are handed over do not guarantee a well-maintained car, and they do not guarantee the long-term reliability of a pump. As stated in NFPA 25, routine inspection, testing, and maintenance (ITM) are essential. Pumps are an essential part of fire sprinkler systems because they provide the volume and pressure required in an emergency. The fire pump flow test becomes an annual necessity to make sure your system functions flawlessly when you need it most, much like sprinklers cannot operate without water flow. Anchor Fire Protection Inc., the fire inspection company, is available to offer you premium services for the fire pump churn test in Los Angeles, you have nothing to worry about.

What is a churn test?

The pressure at which a fire pump churns—that is, when it operates without any water flow—is an essential aspect of its efficiency in an emergency. Regular no-flow (churn) checks make sure the pump starts and runs correctly in zero-flow situations. These 30-minute tests give you important information about the state of your system and enable you to take care of possible problems before they get worse. Make it a mandatory feature of your fire safety plan to prioritize these tests. Monthly “churn” tests and annual flow tests, which guarantee the pump remains ready for operation, are required by NFPA 25 for fire pump inspection.

How is the churn test conducted?

As with any other piece of machinery, regular testing is necessary for maintaining the efficient operation of a fire pump. Let’s get started by looking at the technical churn test procedure. The following five steps will ensure that your fire pump is always prepared for anything.

Preparation

Anchor Fire Protection implements strict safety protocols. The fire pump test header is attached to hoses, which are typically fitted with specialty nozzles. The pump is connected to an appropriate power source, the area is cleared and secured to prevent risks, and all necessary valves are placed in strategic locations. Suction side valves are normally left open, but discharge valves are usually closed. Additionally, fueling with churn water may be required, based on the pump’s specs. Hoses can be attached to the fire pump test header in order to gather data without actually releasing water. Now that everything has been set up, the pump is prepared for its performance assessment.

Run Time

The pump is turned on for ten to thirty minutes, depending on the rules and type of pump. Important variables, including vibration, temperature, and pressure, are closely monitored during this operation. Built-in pressure sensors in fire pump test headers make it easy to monitor pump pressure while the pump is being tested. A complete documentation of each observation is carefully kept for future reference, providing an overview of the pump’s condition and functionality.

Cool Down

The pump is safely shut off and comes to a complete stop after running for the allotted amount of time. A short cooling period allows the pump to settle down before further adjustments. The valves are put back in the positions where they normally operate.

Data Analysis

We do an analysis of the recorded data to find any patterns or values that deviate from the norm. If there are any differences, more research is necessary to determine the underlying reason. All test results and observations are documented for total transparency and for the purpose of planning services for the future.

Wind Up

The pump is considered operational and ready for use if everything functions as it should. If issues surface, the required modifications, fixes, or additional testing may be needed. The next scheduled churn test is decided based on the test findings and guidelines.

Personnel involved in testing need to know the specific details, as described in NFPA 25. It is essential for a safe and efficient operation to rely on competent personnel with the necessary experience and licenses.

Visual and Operational Fire Pump Testing Requirements

We keep a check on the following observations during the fire pump churn testing.

Before The Operation

- Note the initial values of the suction and discharge pressures.

- Note the highest and lowest pressure recorded in the event log for electronic pressure control pumps.

- If beyond the typical range, record pertinent event log information.

During The Operation

- Note the initial pressure, suction, and discharge measurements.

- Check for leaks, overheating, vibration, and noise.

- Check the discharge gauge against the pressure switch reading.

- Record current, the highest and lowest event log pressures for electronic control pumps.

Electrical Framework During The Operation

- Watch the motor accelerate to its maximum speed.

- Take note of the pump run time following startup for automatic stop controllers.

Who needs to perform or witness a churn test?

A three-person crew, typically including an electrician, carries out the fire pump inspection. This electrician measures the electrical amps drawn from the controller at each speed while keeping an eye on the motor’s RPM (turning speed) and direction. Every piece of data is carefully documented for upcoming reporting and analysis. In case the automated inspection and testing do not meet NFPA 25 requirements, trained personnel must always be present when the pump is operating.

Why is a churn test important?

- Fire pump inspection is a sort of preventive care that detects small problems before they become major ones that require expensive repairs or pump breakdowns.

- Churn tests minimize damage and circulate the lubricants necessary for smooth functioning by running without water.

- These tests serve as check-ups, verifying that critical factors such as pressure, churn water flow, and efficiency stick to set norms.

- Churn tests on a regular basis ensure that your fire pump is prepared and set to work as effectively as it can in an emergency.

FAQS

Don’t worry. A churn test may find issues early on, allowing for replacements or repairs, preventing more serious issues later on.

The type of fire pump you are using will determine how much a fire pump churn test will cost. We might evaluate the fire pump to determine the price.

It is best to let the experts handle the fire pump. They can do it safely and effectively because they have the knowledge and tools needed.

Churn tests for fire pumps are typically completed in 10 to 20 minutes.

We keep an eye on vibration, temperature, pressure, and other critical indicators to make sure everything is functioning properly.

You can ask questions and learn important information about the condition of your pump by being present, even if it’s not necessary.

It takes NFPA compliance through numerous inspections and fire pump flow tests to guarantee your fire pump functions perfectly in an emergency. A visual examination finds any physical damage first. The next important step for both diesel and electric pumps is a full-flow test. The test findings are then documented and compared to factory standards and historical performance data to identify variations that require attention. This complete method helps make sure your fire pump is prepared to handle the situation when people and property are at risk.

Necessary preparation is the best defense against disasters and flames. Therefore, safeguard your property with expert fire safety from Anchor Fire Protection. Get in touch with us by phone at +1818-337-3337 or via email at info@anchorfire.net to find out more about how we can maintain the safety and security of your property.

KEEP YOUR PROPERTY SAFE

Related posts

-

Fire Extinguisher Inspection

-

Fire Sprinkler System Components

-

What are the most common types of fire pumps?

-

How much does a fire sprinkler system cost?

-

What is active and passive fire protection?

-

Fire Pump Churn Test

-

Fire Sprinkler System Installation

-

High Rise Fire Safety

-

What is fire compartmentation

-

Fire Pump Testing Requirements: A Step-by-Step Guide to Comprehensive Testing